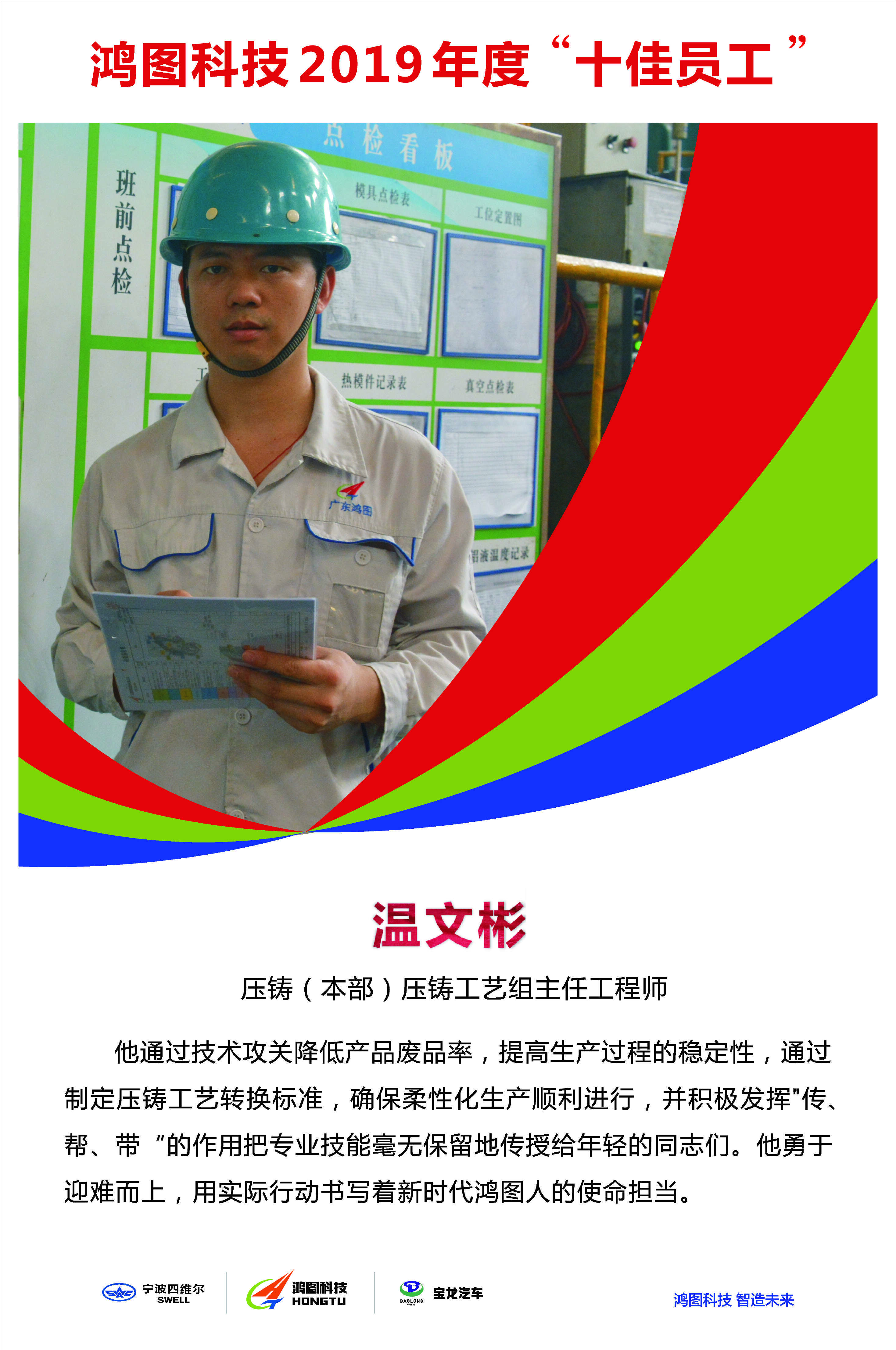

during the time when he served as the product engineer, he managed to make technological breakthrough, which enables a steady reduction in the rejection rate of fca series products and effective control over the stability during the production.

he proactively participated in the company's full value stream improvement, making it possible to optimize the production process of nissan thermostat family, shorten the production cycle and reduce the average production cost.

adhering to the customer-oriented core value, he immediately established a task force to make technical improvement when the company failed to meet customers’ needs for required capacity due to the overlong production cycle of a product. with his efforts, the cooling time of the die was shortened significantly, and the production cycle was reduced to 73 seconds from 95 seconds. as such the customer's requirement is met.

he exerted his authority in the preparation of die-casting technology switching standard, enabling soft switching between die-casting machines of same tonnage, and between imported die-casting machine and domestically-made die-casting machines for most of products. this expands the space for production scheduling and assures that the product is delivered in time.

he compiled the training course measures for die-casting technology commissioning process and basic operation of fanuc robot, which helps standardize the technical process and shorten the commissioning time. in the meantime, he never stops learning new knowledge and new technologies. after his visit to shanghai, japan, zhuhai and other places for die-casting exhibition and technology exchange, he completely imparted the professional skills learnt during the visit to the young generation, performing well in mentoring.

he would rise to the challenge regardless of any difficulties, and demonstrate hongtu men’s mission in the new era with practical actions.